High Precision Deep Drawn Parts at High Production Speeds:

Versatility is unsurpassed over conventional single ram multiple presses and progressive tooling. Our design allows for secondary operations such as beading, knurling, side-piercing and lettering to be performed in high-speed productions, saving you valuable time

Positive Part Control

With positive part control, parts being drawn can remain under full positive control of the tools on the transfer mechanism at all times. We never let go!

Greatly Reduce Your Material Costs

Through the elimination of carrier strips, scrap is automatically reduced. Our C-Series press can accept metal in the form of strip, blank, cup, or preform. The use of a stagger feed system for multiple row blanking provides even lower material cost.

Simplify Tooling With Our C-Series Press:

Our Samson C-Series press is a multi-station, deep draw transfer press that makes lower cost tooling a reality. Tooling consists of simple punches, stripper sleeves, dies inserts, knockout pins, and transfer fingers. All tooling for Samson C-Series Presses are interchangeable with Waterbury Farrel transfer presses.

Modular Die Bed Construction

The modular die bed construction with tight tolerance and keyed die holders provide positive die location and allow single tool stations to be individually adjusted or removed without disturbing adjacent tooling. The modular concept permits the ultimate in tooling simplicity.

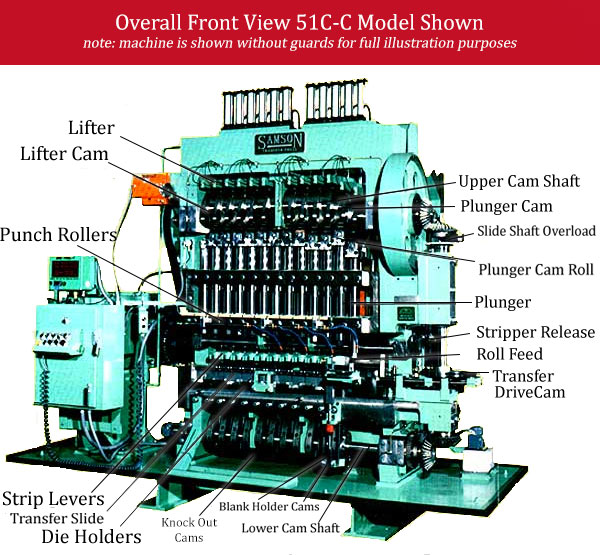

Independent Stations

Samson C-series presses are of multiple plunger construction. Plungers are individually cam operated, each having it’s own down stroke cam and its own lifter cam. These cams are mounted alternately on the upper cam shaft. Tool shut height is adjustable through a wedge mechanism located in each plunger. These independent stations allow for positive part control throughout the entire cycle.

Industries That Benefit:

Our equipment is used worldwide to produce deep drawn components for the Automotive, Bearing, Electrical, Electronic, and Cosmetic Industries, to name a few.

Standard Features

- Machine sound and safety enclosure

- Electrical control circuit

- Operator push button station

- Walkaround push button jog control

- Variable speed adjustable pulley drive

- Digital tool and dies protection system

- Combination air clutch and brake

- Automatic machine lubrication system

- Motor driven die lubrication system

- Mechanical roll feed with indexing clutch

- Mechanical scrap chopper

- Linear bearing transfer drive

- Keyes individual die holders

- Timed delay stripper release motion

- Transfer slide with transfer fingers

- Knockup cams and ejector pins

- Mechanical blank hold down

- 13th Station auxiliary plunger

- Provisions to mount stagger feed

- Provisions to idle 2nd station

Optional Features

- AC variable speed drive

- Beading attachments

- Threading attachments

- Punch accelerator plungers

- Mechanical hold downs

- Stagger feed unit